Scrim Reinforsed VCL Insulation-FSK Material

Price 35.0 INR/ Square Meter

Scrim Reinforsed VCL Insulation-FSK Material Trade Information

- Minimum Order Quantity

- 2000 Square Meters

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 100000 Square Meters Per Month

- Delivery Time

- 10 Days

- Sample Available

- No

- Sample Policy

- Free samples are available

- Packaging Details

- Standard Packaging

- Certifications

- ISO,

About Scrim Reinforsed VCL Insulation-FSK Material

Product Title:

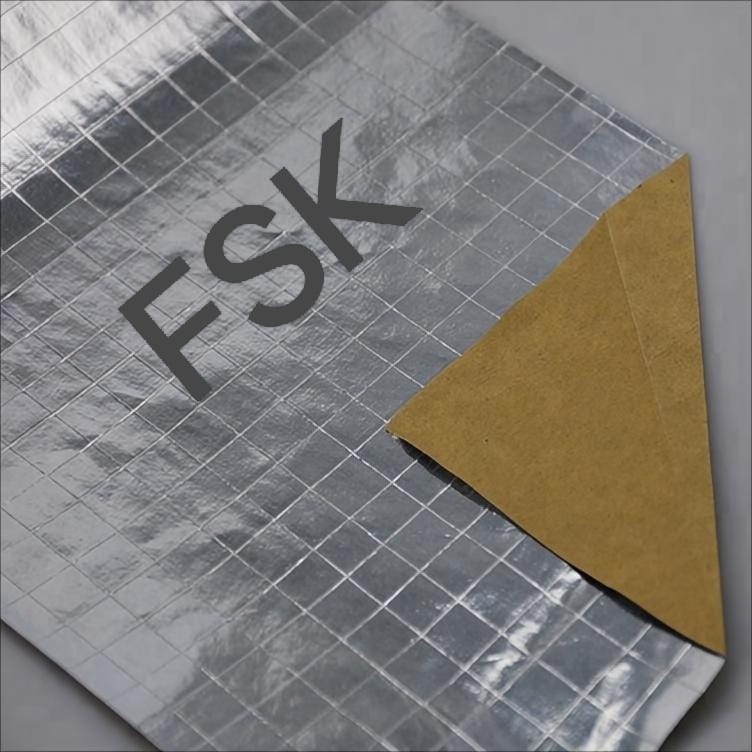

Scrim Reinforced VCL Insulation | FSK Foil-Scrim-Kraft Vapor Control Layer

Product Description:

Our Scrim Reinforced VCL Insulation featuring a high-quality FSK (Foil-Scrim-Kraft) laminateis engineered to serve as a durable and effective Vapor Control Layer (VCL) in insulation systems. This high-performance facing combines aluminium foil, fiberglass scrim, and kraft paper, delivering exceptional moisture resistance, fire retardancy, and mechanical strength.

Designed for use in HVAC ductwork, roof and wall insulation, and industrial applications, this FSK material acts as a reliable radiant barrier, moisture barrier, and insulation facing, ideal for both new construction and retrofit projects.

Key Features:

3-Layer Composite: Foil + Fiberglass Scrim + Kraft Paper

Excellent Vapor Barrier: Controls moisture transmission and prevents condensation

High Reflectivity: Reflects up to 95 -97% of radiant heat

Reinforced with Scrim: Enhanced tear resistance and dimensional stability

Fire Retardant: Meets ASTM E84 Class A fire rating (on request)

Easy to Install: Compatible with adhesives, staples, and mechanical fasteners

Technical Specifications:

Material Type: FSK (Foil-Scrim-Kraft)

Foil Thickness: 7- 18 microns

Scrim Type: Fiberglass mesh

Total Weight: 75 - 120 gsm (customizable)

Width: 1000mm - 1250mm

Roll Length: 50m 200m

Temperature Resistance: -40C to +120C

Fire Rating: ASTM E84 Class A (optional)

Water Vapor Transmission Rate (WVTR): 0.02 g/m24h

Applications:

Roof & Wall Insulation Facing Effective vapor control and heat reflection

HVAC Duct Insulation Wrap Energy-efficient, clean finish

Steel Buildings & Warehouses Radiant barrier for metal roofing systems

Fire-Rated Insulation Systems Used with mineral wool, fiberglass, or foam boards

Industrial Packaging Protective barrier for moisture-sensitive materials

Why Choose Our Scrim Reinforced FSK VCL?

Manufactured using precision lamination technology, our FSK insulation facings are available in standard and custom configurations. We offer bulk supply for OEM, insulation manufacturers, and contractors, with tailored performance specs for your projects needs.

Reliable Temperature Performance

This insulation material excels within a broad temperature range of -40C to +120C, ensuring stability and performance in both extremely cold and hot environments. Its adaptability makes it suitable for a wide range of industrial process conditions and climate zones, safeguarding your installations against fluctuating temperatures.

Durability and Surface Quality

Featuring a smooth, reinforced silver surface, this FSK insulation stands up to mechanical stress and resists tears. The materials robust construction guarantees long-lasting service while maintaining a neat appearance, whether installed behind walls or exposed in industrial environments.

Vapor Control and Energy Efficiency

The foil-scrim-kraft composite layer provides excellent vapor barrier properties, helping prevent condensation and moisture accumulation. This significantly reduces the risk of corrosion, improves energy retention, and boosts the overall efficiency of industrial insulation systems.

FAQs of Scrim Reinforsed VCL Insulation-FSK Material:

Q: How is Scrim Reinforced VCL Insulation-FSK typically installed in industrial settings?

A: This insulation material is generally attached over ductwork, pipes, or building surfaces by mechanical fastening or adhesive. Joints and seams are sealed with compatible FSK tape to maintain a continuous vapor barrier and ensure effective insulation performance.Q: What are the primary benefits of using FSK (Foil-Scrim-Kraft) insulation?

A: FSK insulation provides superior moisture resistance, controls vapor transmission, and enhances energy efficiency. Its durable construction also offers additional mechanical protection, extending the lifespan of the underlying systems.Q: When is it recommended to use Scrim Reinforced VCL Insulation-FSK material?

A: This material is recommended when precise vapor control, energy efficiency, and durability are essentialespecially in temperature-variable or moisture-prone industrial environments, such as plants, process facilities, and storage areas.Q: Where can Scrim Reinforced VCL Insulation-FSK be applied?

A: The material is versatile and suitable for a variety of industrial insulation projects, including HVAC ducting, piping, equipment lagging, and wall lining in factories, warehouses, and manufacturing plants.Q: What is the process for maintaining the installed insulation material?

A: WSimply inspect periodically for any physical damage or breaches in the vapor barrier. If necessary, repair with FSK tape or replace sections to uphold moisture and thermal resistance.Q: Why is the silver, smooth finish important for this insulation product?

A: The smooth silver surface not only enhances the appearance but also reflects radiant heat, provides an additional layer of protection against wear, and allows for easy cleaning and maintenance in exposed installations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese